|

Summary of Operational Checks

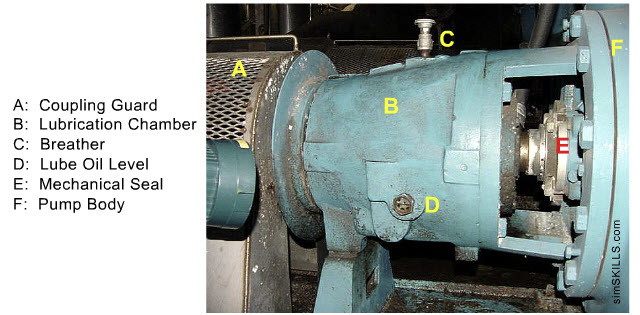

1. Check the coupling guard, make sure it is in place. It is against the law to operate rotating equipment without protective guards.

2. Check bearing temperature. About 150 deg F is normal for a centrifugal pump (each industrial facility has their own temperature standard). The pump bearings are located inside the bearing housing. Normally you check the top of the bearing housing to get an idea about the bearing temperature. To check the bearing temperature, you can touch the housing with your hand or by using an Infra Red Thermometer. For larger and critical pumps, you should keep a record of the bearing temperature. Many of the mechanical problems are indicated by a gradual rise in bearing temperatures.

3. Check the breather - it should not be clogged. The breather allows air to go in and out of the lubricating chamber. During normal operation, the lube oil gets hot, and the air in the chamber expands. The breather allows the hot air to escape. When the oil cools down, some air is sucked back in. The breather is used to filter and dry the air before it is allowed back into the compartment. If the breather is not functioning properly, moist air will get in the chamber and the moisture will condense to form water. This is how water pollutes the lube oil - destroying its lubricating characteristics.

4. Check lube oil level, make sure it is good and the oil is free of debris and foam.

5. Check seal water flowing out of the stuffing box. If it is excessive, tighten the gland nuts a slightly (never more than quarter turn at one time).

6. Mechanical seals also have cooling water flowing through them. Sometimes a flow indicator is provided to indicate the water flow rate. Check to ensure the cooling water flow through the mechanical seals is normal. Listen to the mechanical seal to see if it is making unusual noises. If a mechanical seal gets damaged it starts to overheat. Sometimes overheated mechanical seals make crackling sounds (due to vaporization of cooling water).

7. Listen to the main pump body to see if any cavitation is taking place. If a pump is cavitating it will make a rather loud rumbling noise.

8. Check for abnormal vibration. For minor vibration, take help from a mechanical maintenance person and try to rectify the problem. For excessive vibration it is better to shut the pump down before serious damage occurs.