|

Buckstays

During normal operation, sometimes the furnace experiences some transient high pressure situations, known as “puffs”. These puffs are actually miniscule explosions which occur inside the furnace as small pockets of fuel gets ignited. This is usually a normal situation, and the boilers are designed to handle it in a safe manner.

Furnaces are provided with many provisions to handle minor or major explosions. Details on this subject are beyond the scope of this course.

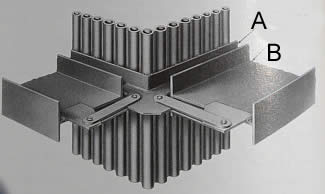

To handle normal miniscule furnace explosions and transient negative pressure conditions, watertube walls are held in place by bars and channels welded to the tubes to form continuous bands around the setting. Such bars are indicated by “A” in the figure.

The furnace assembly is also provided with beams (also known as “buckstays”) which are attached to the tie bars. In the illustration, buckstays are indicated by “B”. The buckstays are connected to each other by means of slip connections, which allow the furnace wall to move inward or outward slightly in response to furnace pressure transients.