|

Oil lubrication

Some rotating shafts are fitted with sleeve bearings. A sleeve bearing is usually a soft brass cylinder that fits around the machine-shaft journal like a sleeve. In some installations, lubricating oil is circulated through the sleeve bearings under pressure. Some sleeve bearings, however, may be lubricated by means of an oil ring.

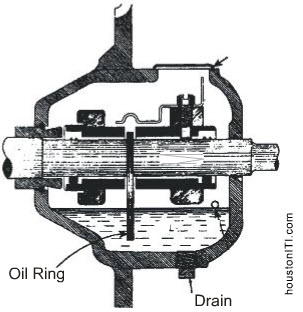

The figure provided here illustrates how an oil ring works. The loose ring hanging on the journal moves and jumps around as the shaft revolves. As the oil ring rotates, it dips into an oil reservoir directly beneath the shaft journal. The oil picked up by the ring is then splashed along the shaft, between the shaft journal and sleeve bearing.

Proper lubrication of ring-oiled sleeve bearings depends on maintaining a sufficient oil level in the reservoir. For this reason, most sleeve bearings are provided with an oil level monitoring system – such as a view port.