|

Transformers - continued.

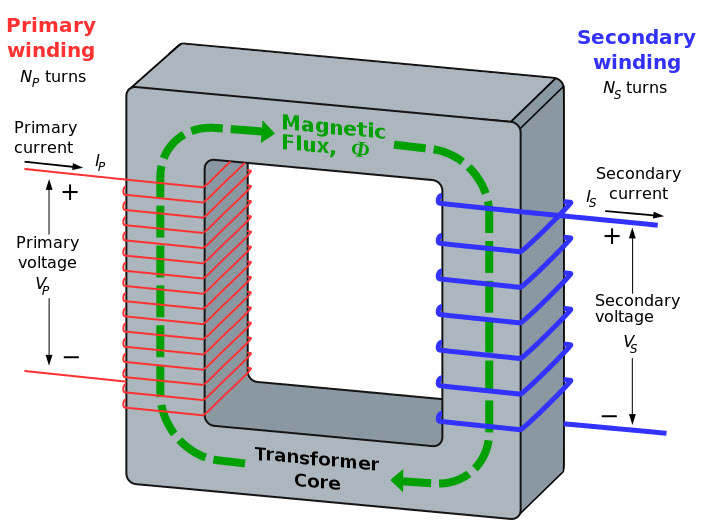

In its simplest form, a transformer consists of two windings or coils wrapped around a metallic core. When one coil is energized by AC, a voltage is induced in the other coil. The three basic elements of a transformer are:

a. Primary coil

b. Secondary coil

c. Core to support windings (coils)

In the graphic provided here we illustrate a magnetic core around which the primary and secondary coils are wrapped. In reality the core is designed in many ways. The simplest (and least efficient) way is to wrap the secondary winding directly over the primary winding - with no core inside - or we can say around air. Also, this figure illustrates the transformer action in a simplistic manner - in the real life, almost always for windings for a given phase, the two windings (primary and secondary) are wound on top of each other - this improves efficiency of voltage transformation.

The figure shown here illustrates the magnetic core which is designed to support the coils. The three most common elements used as the transformer core are:

a. Air

b. Soft iron

c. Steel

A soft iron or steel core is far more efficient than an air core. To further enhance the efficiency and performance, the core is constructed by bundling thin sheets of steel rather than molding solid material.

In the figure we show a solid core - but in reality it is much better to create solid iron which is made of a large number of plates referred to as laminations. The solid core is shown for for the sake of simplicity - in real life, almost always laminated cores are used.

Note: Some of the material shown in this graphic is beyond the scope of this module. It is shown here for the sake of completion - to be built upon in other modules.