|

Worn Out Packing

Over time, packing wears out. As a result, leakage through the stuffing box increases. To improve the sealing action of the packing, the operators tighten the gland nuts. This results in reduction in leakage and system is restored to normal operation. However, there is a limit to how much you can keep on tightening worn out packing.

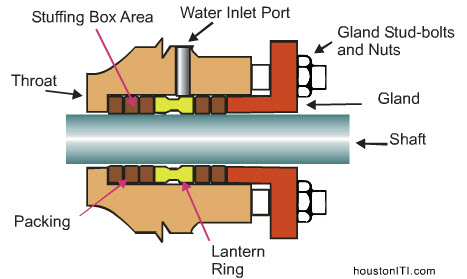

The figure provided here illustrates worn out packing (notice on the lower side - some space between the shaft and the packing material.) Notice that the lantern ring is no longer in proximity of the inlet water line. In this case, incoming water flow is reduced to a great extent. That obviously results in loss of lubrication and overheating of the packing/shaft interface. Eventually this results in damage to the pump drive shaft.